A round pipe of varying diameter carries petroleum – The utilization of round pipes with varying diameters for the transportation of petroleum is a topic of paramount significance in the realm of fluid dynamics. This intricate system plays a pivotal role in the global energy landscape, necessitating a comprehensive understanding of its design, operation, and maintenance.

This discourse delves into the complexities of round pipes with varying diameters, exploring their applications in petroleum transportation, the governing fluid dynamics, and the critical design considerations. Moreover, it emphasizes the importance of regular maintenance and inspection to ensure the safe and efficient operation of these pipelines.

1. Pipe Description

A round pipe of varying diameter is a cylindrical conduit with a cross-sectional area that changes along its length. This variation in diameter allows for specific flow characteristics and serves various purposes in fluid transportation systems. The varying diameter can create zones of increased or decreased flow velocity, leading to tailored flow patterns and pressure distributions.

Examples of real-world applications include:

- Pipelines for transporting petroleum products, where varying diameter allows for optimization of flow rates and pressure management.

- Water distribution systems, where varying diameter pipes enable the adjustment of flow rates to different sections of the network.

- Industrial process lines, where varying diameter pipes facilitate the control of fluid flow for specific process requirements.

2. Petroleum Transportation

Pipes play a crucial role in the transportation of petroleum, enabling the efficient and cost-effective movement of crude oil and refined products over long distances. Round pipes are commonly used due to their structural integrity and ability to withstand high pressures.

Advantages of using round pipes for petroleum transportation include:

- High strength-to-weight ratio, providing durability and resistance to deformation.

- Smooth interior surface, minimizing friction and promoting efficient flow.

- Ability to handle high pressures and temperatures, ensuring safe and reliable transportation.

Factors influencing the choice of pipe diameter for petroleum transportation include:

- Volume of petroleum to be transported

- Distance and elevation of the pipeline

- Flow velocity and pressure requirements

- Cost and availability of materials

3. Fluid Dynamics

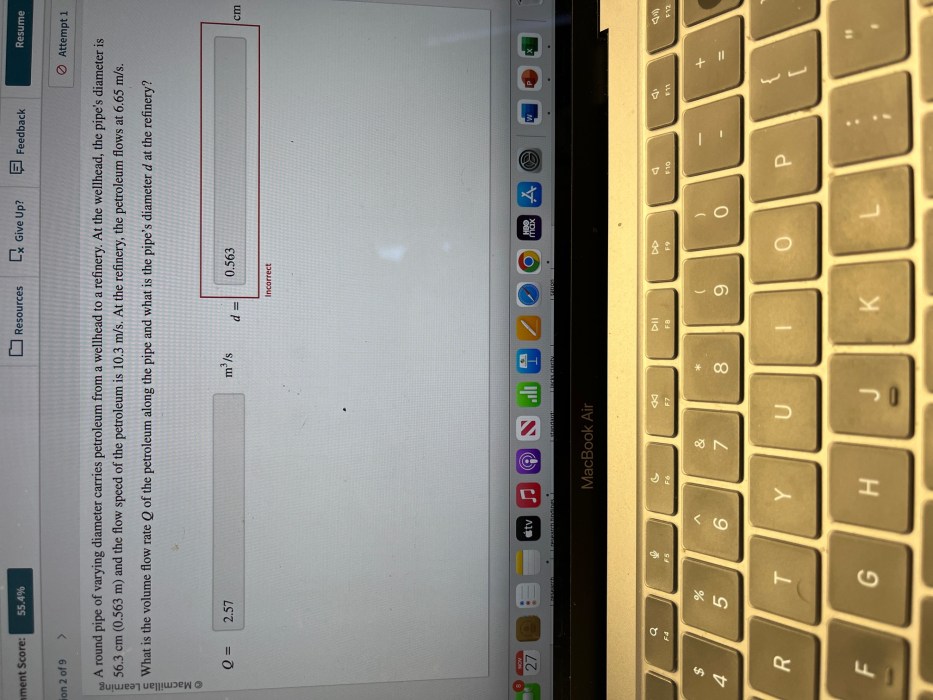

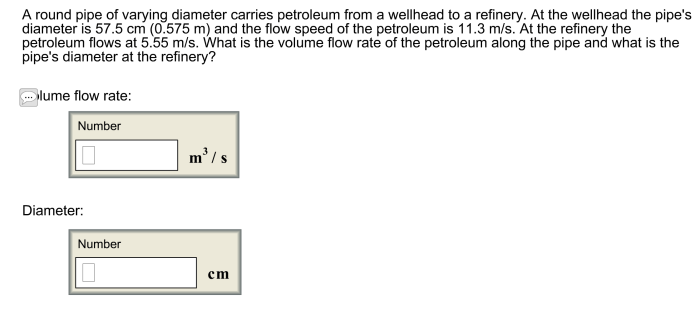

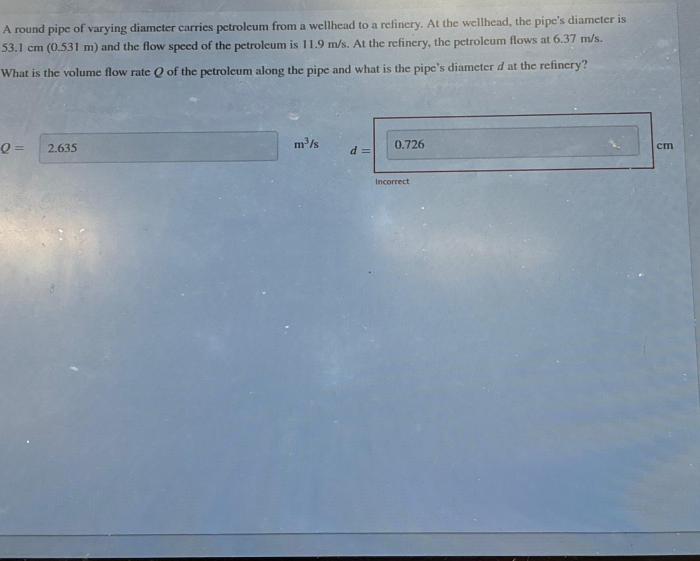

The flow of petroleum through a round pipe of varying diameter involves complex fluid dynamics. The variation in diameter affects the flow velocity, pressure drop, and overall efficiency of the system.

The relationship between pipe diameter and fluid velocity is inversely proportional. As the diameter increases, the velocity decreases due to the increased cross-sectional area available for flow.

Varying diameter can impact pressure drop along the pipe. Narrower sections create higher pressure drops due to increased friction, while wider sections result in lower pressure drops. This variation can be utilized to control pressure distribution and prevent excessive pressure buildup.

4. Design Considerations: A Round Pipe Of Varying Diameter Carries Petroleum

The design of a round pipe of varying diameter for petroleum transportation involves careful consideration of material selection, wall thickness, corrosion resistance, and the integrity of joints and fittings.

Material selection is critical to ensure the pipe’s ability to withstand the harsh conditions encountered during petroleum transportation. Common materials include steel, stainless steel, and polyethylene.

Wall thickness is determined based on the pressure rating and mechanical strength requirements. Adequate wall thickness ensures the pipe’s structural integrity and prevents failure due to pressure or external forces.

Corrosion resistance is essential to protect the pipe from degradation caused by exposure to corrosive substances, such as hydrogen sulfide or salt water. Protective coatings or corrosion-resistant materials are often employed to enhance durability.

Joints and fittings play a vital role in maintaining the integrity of the pipe. They must be properly designed and installed to prevent leaks and ensure a continuous flow of petroleum.

5. Maintenance and Inspection

Regular maintenance and inspection are crucial to ensure the safe and efficient operation of a round pipe of varying diameter used for petroleum transportation.

Maintenance involves leak detection and repair. Leaks can occur due to corrosion, damage, or faulty joints. Regular inspections using non-destructive testing techniques, such as ultrasonic testing or radiography, help identify potential leaks and prevent catastrophic failures.

Inspections also assess the overall condition of the pipe, including corrosion, wear, and structural integrity. This information is used to determine the need for repairs or replacement and to optimize maintenance schedules.

FAQ Compilation

What are the advantages of using round pipes for petroleum transportation?

Round pipes offer several advantages, including structural stability, ease of fabrication, and efficient flow characteristics, making them the preferred choice for petroleum transportation.

How does varying pipe diameter impact fluid flow?

Varying pipe diameter affects fluid flow by altering the velocity and pressure distribution within the pipe. Smaller diameters increase velocity and pressure drop, while larger diameters reduce velocity and pressure drop.

What are the key design considerations for round pipes used in petroleum transportation?

Critical design considerations include material selection for corrosion resistance, wall thickness to withstand internal pressure, and the incorporation of joints and fittings to ensure pipeline integrity.