Introducing the diagram of a fire hydrant, a vital piece of firefighting equipment that ensures a steady flow of water to combat blazes. This guide delves into the intricacies of fire hydrant construction, operation, and maintenance, providing a comprehensive understanding of these essential tools.

From identifying the structural components to explaining the process of connecting a fire hose, this guide covers every aspect of fire hydrant operation. It also explores the different types of hydrants, emphasizing their advantages and disadvantages, and highlights the importance of regular maintenance and inspection to ensure optimal performance.

Fire Hydrant Overview

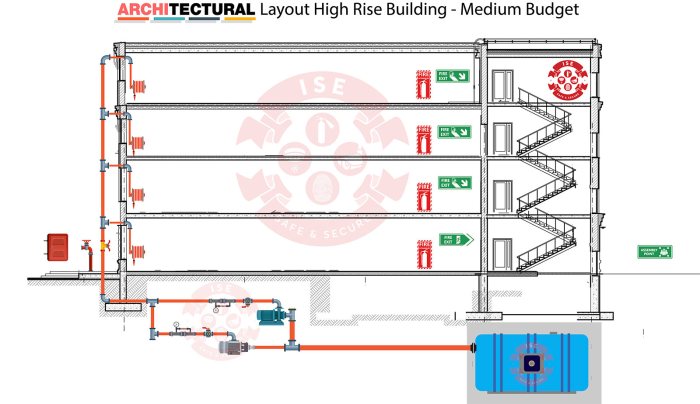

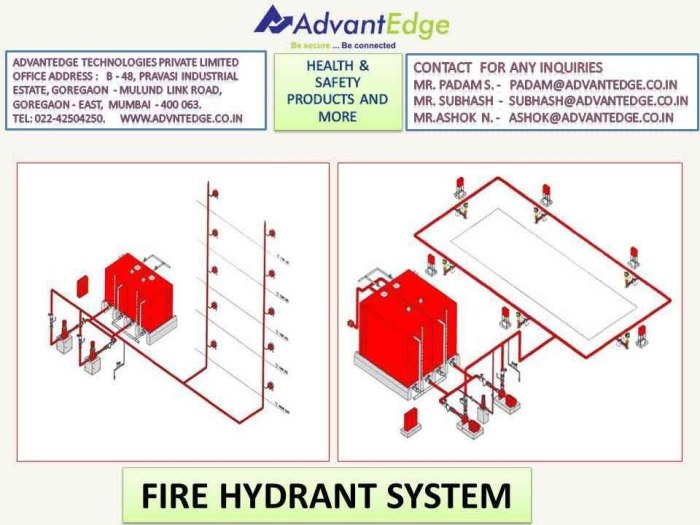

Fire hydrants are essential components of fire protection systems, providing a reliable source of water for firefighting operations. They are typically located in urban and suburban areas, where they are easily accessible to firefighters in case of an emergency.

Fire hydrants are typically made of cast iron or ductile iron and have a cylindrical shape. They range in size from small, residential models to large, commercial-grade units. The size of a fire hydrant is determined by the amount of water flow required for the specific area it serves.

Materials Used

- Cast iron: A durable and corrosion-resistant material commonly used in fire hydrant construction.

- Ductile iron: A stronger and more flexible material than cast iron, often used in areas with higher water pressure or seismic activity.

Structural Components

A fire hydrant is a crucial component of any fire protection system, providing a readily available water source for firefighters to extinguish blazes. Its design incorporates several key structural components that work together to ensure efficient and reliable operation.

The main structural components of a fire hydrant include the barrel, cap, and nozzles. Each component plays a specific role in the hydrant’s operation and contributes to its overall effectiveness in providing water for firefighting purposes.

Barrel

The barrel is the central cylindrical body of the fire hydrant, typically made of cast iron or ductile iron. It houses the internal mechanisms of the hydrant, including the valve assembly and the standpipe. The barrel is designed to withstand high water pressure and provide a sturdy base for the other components.

Cap

The cap is a removable cover that fits over the top of the barrel. It protects the internal components from debris, dirt, and moisture when the hydrant is not in use. The cap is typically made of cast iron or brass and is secured to the barrel with bolts or screws.

Nozzles

Fire hydrants typically have two or more nozzles, which are outlets for connecting hoses to draw water from the hydrant. Nozzles are typically made of brass or aluminum and are designed to fit standard fire hose couplings. They may be equipped with valves to control the flow of water.

A diagram of a fire hydrant can provide valuable information about its components and functionality. For example, it can show the location of the valve that controls the water flow, as well as the diameter of the pipe that connects the hydrant to the water main.

These details can be crucial for firefighters when they are responding to an emergency. In addition to being informative, a diagram of a fire hydrant can also be visually appealing. For instance, some diagrams incorporate images of flowers, such as nancy va a esas flores . These images can add a touch of beauty to an otherwise technical document.

Connection and Operation: Diagram Of A Fire Hydrant

Fire hydrants provide an essential connection point for firefighters to access water for extinguishing fires. Understanding the process of connecting a fire hose and operating the hydrant valve is crucial for efficient firefighting operations.

Connecting a Fire Hose, Diagram of a fire hydrant

To connect a fire hose to a fire hydrant, follow these steps:

- Locate the hydrant and ensure it is in good condition.

- Remove the cap from the hydrant outlet and inspect the threads.

- Attach the fire hose to the outlet by aligning the threads and tightening it securely using a hydrant wrench.

Opening and Closing the Hydrant Valve

The hydrant valve controls the flow of water from the hydrant. To open the valve:

- Locate the valve handle on top of the hydrant.

- Use a hydrant wrench to turn the handle clockwise to open the valve.

- Monitor the water pressure and adjust the valve accordingly.

To close the valve:

- Turn the valve handle counterclockwise using a hydrant wrench.

- Tighten the valve securely to prevent leaks.

Water Flow and Pressure

The flow rate and pressure of water from a fire hydrant are critical factors for effective firefighting operations. Several factors influence these parameters, including:

Water Main Size and Condition

- Larger water mains can deliver higher flow rates and maintain adequate pressure.

- Old or damaged water mains can restrict flow and reduce pressure.

Hydrant Type and Condition

- Different hydrant types have varying flow capacities.

- Proper maintenance and inspection ensure optimal performance.

Demand on the System

- Simultaneous use of multiple hydrants can reduce flow rates and pressure.

- Large fires or other water-intensive operations can deplete system resources.

Importance of Adequate Water Pressure

Maintaining adequate water pressure is essential for firefighting because:

- It ensures sufficient water flow to reach the fire.

- It enables firefighters to use hoses and nozzles effectively.

- It helps prevent the spread of the fire and protects firefighters and property.

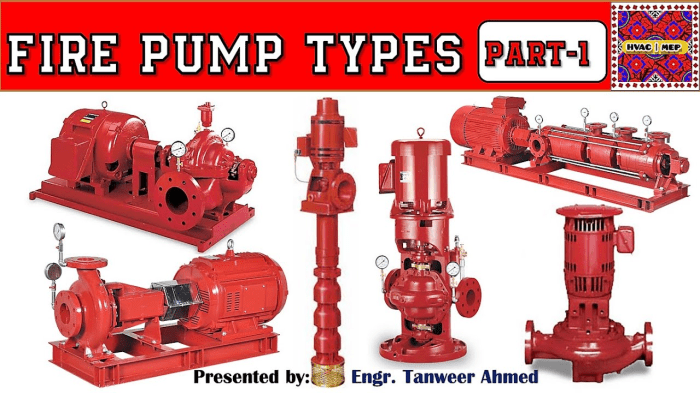

Types of Fire Hydrants

Fire hydrants come in various types, each designed for specific applications and environments. Two common types are dry barrel hydrants and wet barrel hydrants.

Dry Barrel Hydrants

Dry barrel hydrants are installed in areas where freezing temperatures are common. They have a barrel that remains empty above ground, preventing water from freezing and damaging the hydrant. When activated, water flows from an underground source through a valve into the barrel and up through the standpipe.Advantages:

- Prevent freezing and damage in cold climates

- Suitable for areas with fluctuating water pressure

Disadvantages:

- Slower to operate than wet barrel hydrants

- Require more maintenance

Wet Barrel Hydrants

Wet barrel hydrants have a barrel that is constantly filled with water, allowing for immediate water flow when activated. They are commonly used in areas with moderate to warm climates.Advantages:

- Faster to operate than dry barrel hydrants

- Less maintenance required

Disadvantages:

- Prone to freezing in cold climates

- Water can leak or spray when not in use

Maintenance and Inspection

Regular maintenance and inspection of fire hydrants are critical for ensuring their proper operation in an emergency. Hydrants should be inspected and tested annually or more frequently, depending on local regulations and the hydrant’s usage.

Hydrant maintenance involves checking the hydrant’s exterior for damage, corrosion, or leaks. The interior is also inspected for any obstructions or debris that could impede water flow. The hydrant’s valves are operated to ensure they are functioning correctly and that there are no leaks.

Testing Procedures

Hydrant testing typically involves connecting a pressure gauge to the hydrant and flowing water through it at a specified rate. The pressure and flow rate are recorded and compared to the manufacturer’s specifications. This test verifies that the hydrant is delivering the required water flow and pressure for firefighting operations.

By conducting regular maintenance and inspection, fire departments can ensure that their hydrants are in good working order and ready to provide the necessary water supply in the event of a fire.

Safety Considerations

Fire hydrants, while essential for firefighting, pose potential hazards that must be addressed. Understanding these hazards and adhering to safety precautions is crucial for anyone operating or working near fire hydrants.

One significant hazard is the high water pressure within fire hydrants. Opening a hydrant without proper equipment can result in uncontrolled water flow, potentially causing injury or damage to property. Additionally, the force of the water can dislodge the hydrant, leading to further hazards.

Personal Safety

- Always wear appropriate protective gear, including gloves and eye protection, when operating a fire hydrant.

- Stand clear of the hydrant when opening or closing it to avoid being struck by the water jet.

- Never attempt to open a hydrant with bare hands or using tools that are not designed for the task.

- If a hydrant is damaged or leaking, report it immediately and do not attempt to repair it yourself.

Equipment Safety

- Use only authorized tools and equipment to open and close fire hydrants.

- Ensure that the equipment is in good working condition and free from defects.

- Follow manufacturer’s instructions for proper use and maintenance of the equipment.

Environmental Safety

- Be aware of the potential for water runoff when opening a fire hydrant.

- Take measures to prevent damage to property or the environment, such as directing the water flow away from sensitive areas.

- Report any spills or leaks promptly to the appropriate authorities.

Visual Representation

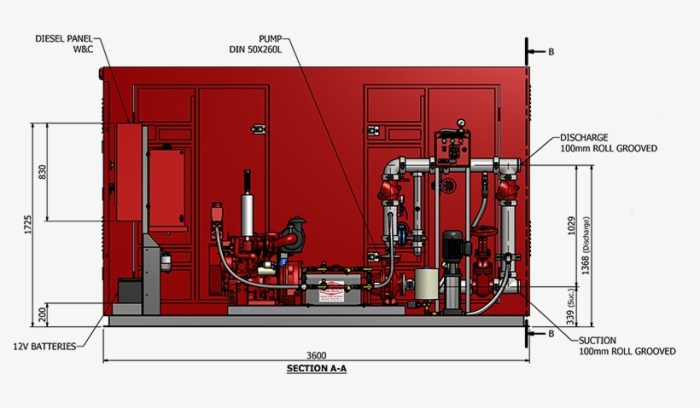

A fire hydrant is a critical component of any fire protection system. It provides access to water for firefighters to extinguish fires. Fire hydrants come in various sizes and types, but they all share some common components.

The diagram below shows a detailed representation of a typical fire hydrant, labeled with its major components:

| Component | Description |

|---|---|

| Barrel | The main body of the hydrant, which contains the water |

| Bonnet | The top of the hydrant, which houses the operating mechanism |

| Stem | The shaft that connects the bonnet to the valve |

| Valve | The mechanism that controls the flow of water |

| Nozzle | The outlet of the hydrant, where the fire hose is attached |

| Cap | The cover that protects the nozzle |

| Flange | The base of the hydrant, which is bolted to the water main |

| Gate | The part of the valve that opens and closes to control the flow of water |

| Seat | The part of the valve that the gate closes against |

| Packing | The material that seals the valve stem to prevent leaks |

FAQ Overview

What is the purpose of a fire hydrant?

Fire hydrants provide a readily accessible source of water for firefighters to extinguish fires.

How does a fire hydrant work?

When a fire hose is connected to a fire hydrant, water flows from the hydrant’s barrel through the hose to the nozzle, where it is discharged.

What are the different types of fire hydrants?

There are two main types of fire hydrants: dry barrel hydrants and wet barrel hydrants. Dry barrel hydrants are located below ground level and only fill with water when they are opened, while wet barrel hydrants are constantly filled with water.

How often should fire hydrants be inspected?

Fire hydrants should be inspected annually to ensure they are in good working order.